Machine protection in many ways.

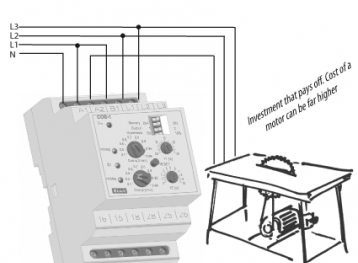

By investing in additional machine protection, especially motors (monitoring the overload and underload, overheating, winding overload, overcurrent, or hazardous voltage lower tier) can be at relatively very low cost for the protective device to eliminate possible high losses incurred damage or their complete destruction, for the relatively low cost of the protection devices. The underestimation of the risks associated with the connection to the power supply network as well as the influence of the operators connected with the operation of these devices are not in most cases paid.

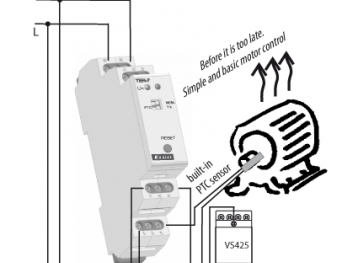

Particularly with today's motors, where PTC thermistors are also often fitted into the winding to quickly evaluate the actual engine temperature, it is very convenient to use thermistor relays like the TER-7etc. The relays then control the winding temperature via the built-in PTC. The resistance of such a sensor outside of the motor in the cold state is of 1.5 kΩ. When the temperature increases, its resistance increases sharply, and when the 3.3kΩ limit is exceeded, the output relay contact disables (mostly contactor controlling) the motor. The TER-7 has, for example, sensor fault monitoring, which controls the interruption and disconnection of the sensor. Another security feature is MEMORY. If the temperature is exceeded (and the output is switched off), the output remains in the error state until the operator intervenes. Operation is of course available in such a state by way of the reset button.

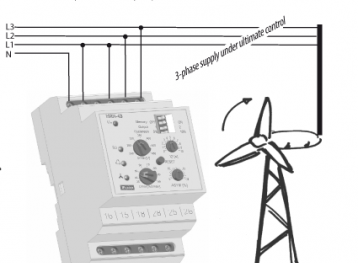

Surveillance of overheating by means of thermistors is very effective protection, but due to the temperature dependence there are some delays in the evaluation. This protection is suitable, for example, for the phase failure monitoring, or for monitoring the interruption of the working conductor. If it is required to monitor under voltage or sequence of phases or asymmetries, it is desirable to install a multi-monitoring device, for example, HRN-43 (comparison of the phase-to-phase voltage) or its HRN-43N variant (the principle of comparing the phases to the working conductor "N", where it also monitors its interruption.

An interesting area is also the protection for the current power factor cos (fi).

Monitoring of the relief or overloading (motors, pumps, etc.), where excessive load may result in the state that energy is supplied to the device, but it is not enough for example for the operation of rotary machines, and the winding is overloaded above the set limit, which leads to machine stop or the motor burning out.

For pumps, the change state is the opposite. If the pump runs idle and is not loaded and cooled enough it may be damaged due to its inadequate speed. Pumps equipped with a floating probe do not have to shut down in the event of a jam, so it is a good idea to assure the function of a similar device. For this purpose, the COS-1 Power Factor can be used.

The machine has the so-called time to eliminate the fault condition (motor start), which is signalled by flashing yellow LED, during this time the outputs are permanently closed. And if the load is disconnected, this LED lights up and the two relays are switched on again. In the event that (Cos-φ-max) or (Cos- φ -min) the corresponding output for the upper or lower level is opened.

Therefore, it really endeavours to protect the specific machines. Depending on the application, we can find other monitoring and disconnection devices. Without installing security features, there is a lot of risk, do we ever think about how big it is?

Customer Centre

Technical support

| +91 90816 69666 | |

| mahamunkar@elkoep.in |

| +91 90816 69666 | |

| elko@elkoep.in |

E-shop

E-shop

Česky

Česky

Slovensky

Slovensky

English

English

Deutsch

Deutsch

Polski

Polski

Български

Български

Magyar

Magyar

Românește

Românește

Tiếng việt

Tiếng việt

Ukraine

Ukraine

Español

Español

English GB

English GB

Српски

Српски